Autonomous Vertical Garden

Overview

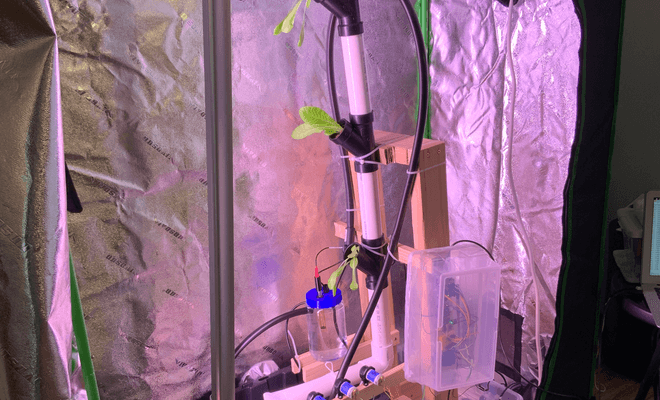

I utilized my knowledge of software development, microcontrollers, sensors and peristaltic pumps to constantly monitor and adjust nutrient and pH levels of the water environment for a hydroponic vertical garden. I designed and implemented the autonomous control system for the water environment. The project was built using materials avaiable at most local hardware stores and the sensors and pumps were from various online vendors.

Motivation

As someone who is interested in sustainability, robotics and software I was excited to have the opportunity to combine these skills to create a autonomous hydroponic vertical garden that optimizes plant growth. At the time, the market options for this were expensive and I wanted to see if it would be possible to also optimize cost while optimzing plant growth. Another motivating factor was to try and address and combat the problems of the current argicultural sectors excessive water use, use of pestisides, large physical footprint and costs.

Features

Lets break the title down to discover the features:

- Autonomous - The garden is capable of continuously monitoring and maintaining an optimized water environment without any human intervention necessary.

- Hydroponic Nutrient Delivery - The garden utilizes hydroponics to deliver nutrients directly to the plant roots, promoting healthy growth and efficient resource use.

- Space-Saving Design - The garden's vertical layout maximizes space usage and takes advantage of gravity, allowing for more plants to be grown in a smaller area.

- Precision Optimization - The garden's pH and solute sensors, peristaltic pumps, and software work together to constantly monitor and optimize nutrient and pH levels, ensuring that plants receive the ideal conditions for optimal growth.

Outcome/Result

The project was a resounding success in producing improved lettuce growth by leveraging an Arduino microcontroller to monitor the pH and solute levels of the hydroponic system's water environment. The system can operate without any human intervention. By sampling the water environment at regular intervals, the microcontroller receives information from pH and total dissolved solids (TDS) sensors and uses peristaltic pumps to achieve the appropriate nutrient and pH levels. This constant monitoring ensures that the plants, in this case lettuce, receive optimal nutrients at the correct pH level directly to their roots, promoting accelerated growth. Furthermore, the consistent water environment, combined with the use of grow lights, further supports optimal plant growth.